Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Detailed Introduction:

I. Overview:

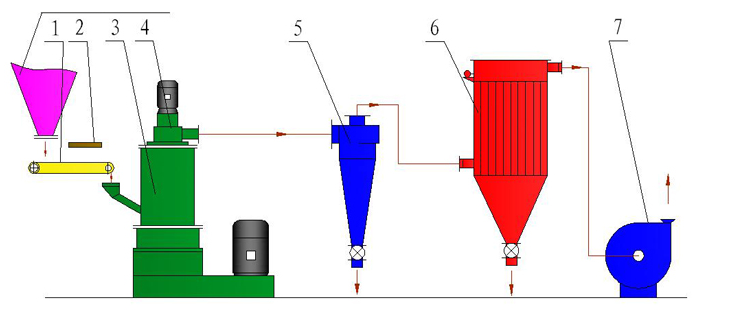

After coarse crushing, the material is transported to the main machine's crushing chamber by the feeding device. Inside the chamber, the material undergoes ultrafine crushing through mutual impact, collision, friction, shearing, and extrusion with high-speed rotating components and particles. The crushed material is then transported to the impeller classification zone by an ascending airflow. Under the action of the centrifugal force of the Classifier Wheel and the suction force of the fan, coarse and fine powders are separated. The qualified fine powder is collected by a cyclone collector, while the unqualified powder is returned to the crushing chamber for further grinding by the internal classifier. The purified gas is discharged by the induced draft fan.

II. Features:

Low Energy Consumption: Combining centrifugal crushing, impact crushing, and extrusion crushing, it saves up to 30% more energy than similar mechanical crushers.

High Fineness: Equipped with a high-precision grading system, the product fineness can be adjusted freely to achieve an ultra-narrow normal distribution curve of materials.

Low Wear: The wearing parts of the crushing section are made of composite wear-resistant new materials, ensuring long service life and almost no pollution when processing materials with Mohs hardness ≤5.

Strong Mechanical Stability: It can operate continuously for 24 hours without stopping.

Negative Pressure Production: No dust pollution, ensuring an excellent environment.

Shaping Function: The equipment has a shaping function and is highly automated, stable, and easy to operate.

High Purity: Customized accessories can be made according to material requirements to ensure no secondary pollution during production and maintain product purity.

III. Technical Parameters:

| Equipment Model | Installed Power (KW) | Feed Particle Size (mm) | Discharge Particle Size (μm) | Output (kg/h) | Remarks |

|---|---|---|---|---|---|

| SCWN-200-2 | 22 | ≤5 | 5-45 | 20-200 | Adjustable particle size |

| SCWN-300-2 | 30 | ≤5 | 5-45 | 50-300 | Adjustable particle size |

| SCWN-400-2 | 50 | ≤5 | 5-45 | 100-500 | Adjustable particle size |

Product Categories : Special Equipment

Home > Products > Special Equipment > crushing and classification equipment for natural graphite

Send Inquiry

Mr. John Zhou

Tel:

Fax:

Mobile Phone:++86 19982722770

Email:zihan.zhou@scwnkj.com

Address:About 140 meters east of the Olive Garden (Yuanxing West Street), Caiyuan Road, Fucheng District, Mianyang, Mianyang, Sichuan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.